Minerals Processing

Process Plants International has extensive experience in providing design, construction, commissioning and maintenance on complex minerals processing plants.

We understand the chemistry, equipment, materials and operational factors that go into getting a plant to operate at its peak performance. Our team can provide optimisation across all areas of your plant to ensure you are getting the best from what you have.

No one approach addresses a processing plants complex operating issues. Plant stabilty is key to successful operations. Plant stability is achieved by implementing sound operating philosophies supported with the associated control systems and maintenance programs.

Process Plants International can assess your plants performance, identify a clear path for improvement, and implement those changes regardless of whether they are coding or in field installation of additional instrumentation or equipment. We can collate maintenance shutdown schedules and provide the teams to execute them in any country in the world. This includes engaging engineering, site supervision and trade labour to implement work whether it be construction, commissioning, or maintenance. Depending on your projects location, Process Plants International employs a large number of skilled third country nationals to lower our overall costs to clients.

Process Plants International key business functions;

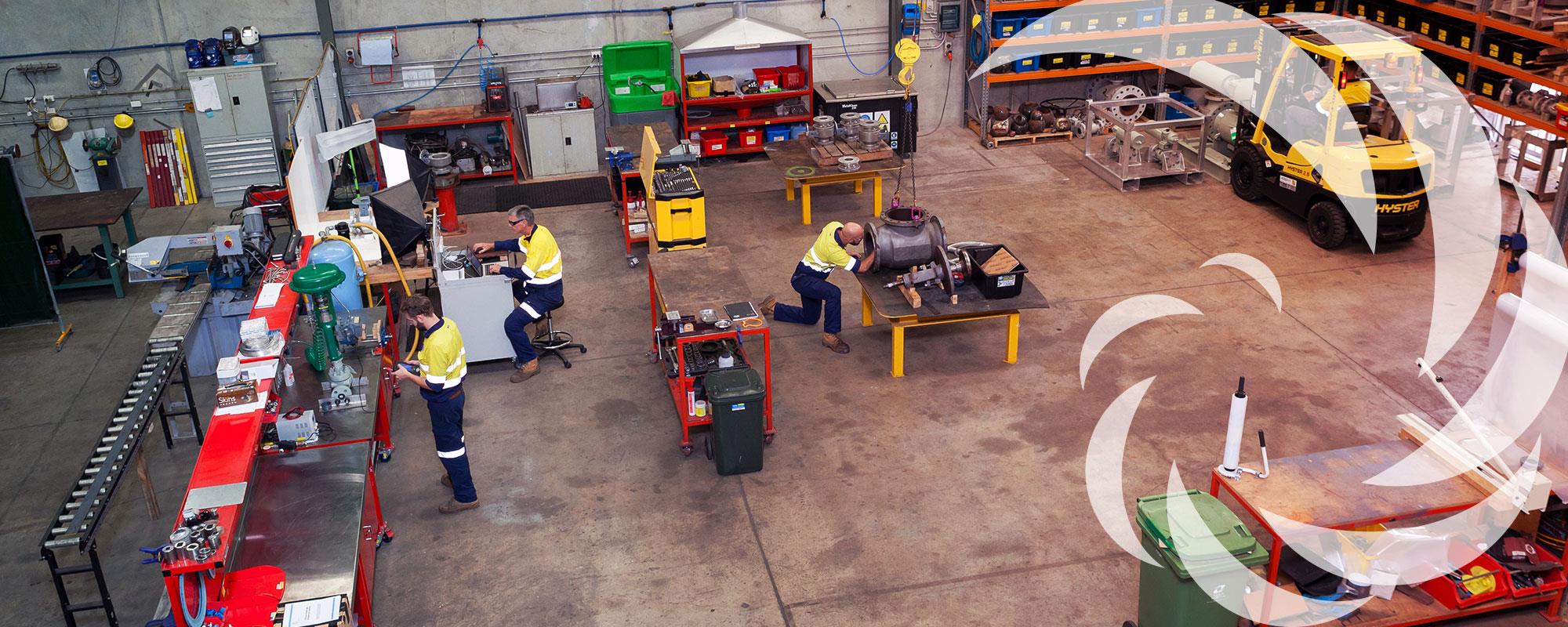

- Support of all operating site maintenance functions via, mechanical, electrical and instrumentation trades as well as engineering support from process, mechanical and electrical engineers

- Industrial processing plant optimisation to achieve increased performance and operational stability through design and operational review

- Severe service and commodity valve overhaul, repair, modification, pressure testing, cleaning and certification for oxygen service.

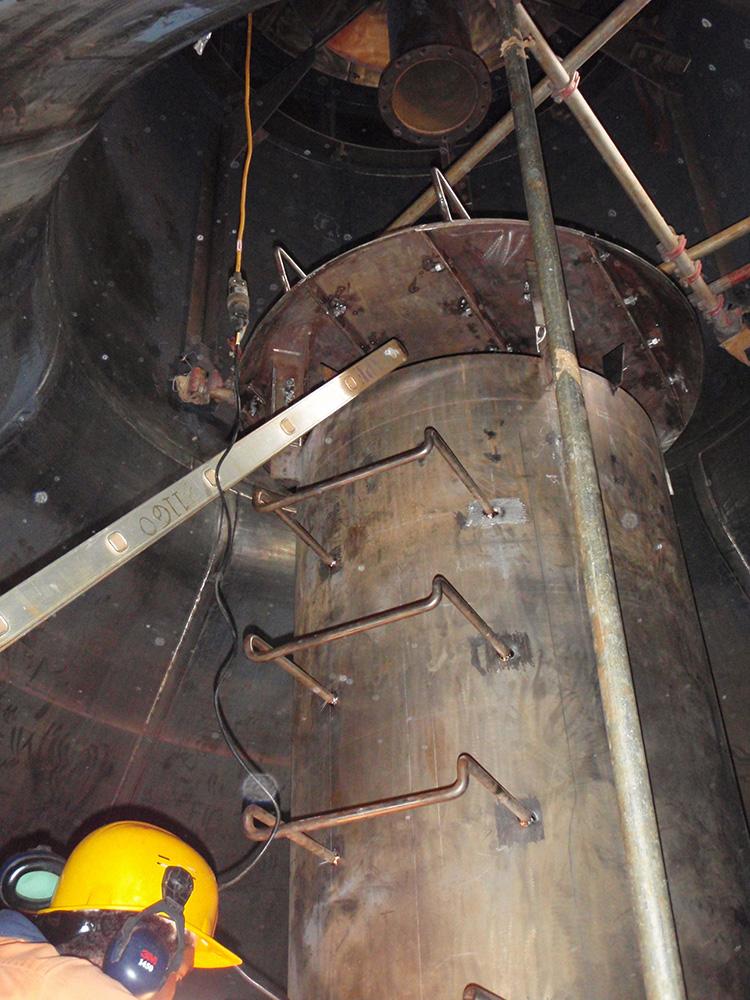

- Certified welders and inspectors

- Pipework fabrication. using carbon steel and exotic materials

- Drafting services

- 3D modelling and inspection of pipework and mechanical components

- Thermal ceramic coatings

- Repair and modifications of rotating equipment, pumps and gearboxes

- Comprehensive outage and shutdown experience and capabilities. Outage development and planning from scope of work, scheduling, workpack creation, procurement and execution management

- Extensive engineering and maintenance resources to support equipment both in the workshop and with field service capabilities