Flow Chart of Process

Identify fatal flaws and rectify.

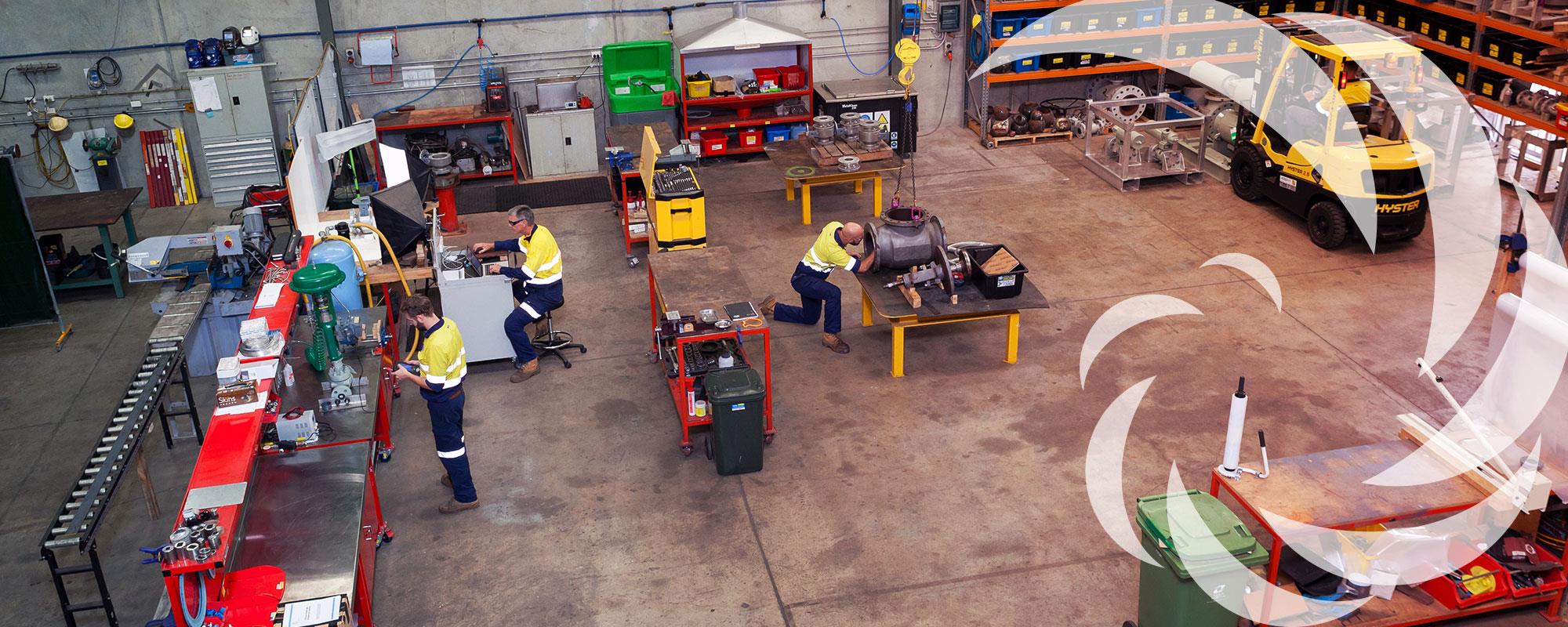

Ensure equipment is appropriate for the job.

Correct installation of mechanical equipment and piping, change management, project schedule aligned with commissioning logic.

Rigorous staged approach using database tracking. Design and construction errors identified and rectified using change management. Initial plant shutdowns planned and implemented. Client education and support during handover.

Supervision provided for transition into operation with a focus on production.

On the job and in classroom, adapted to suit the skills of our client’s employees.

Our engineering and trade expertise have developed from experience in maintaining autoclaves and associated equipment. HPAL plants are operated under some of the most arduous conditions for mineral processing. Our maintenance approach is centered on extending campaign run times as confidence in critical components is gained.

PPi has a reputation as the can do company, based on seamlessly executed projects in such widely disparate landscapes as the deserts of Western Australia, jungles of New Guinea and winters of Central Turkiye. Wherever your next HPAL and POX projects, consider PPi as your first port of call.