About Process Plants International

PPi was created to support clients with the arduous duties of operating and maintaining complex processing plants in the Minerals and Oil and Gas industries.

PPi hand-picks the appropriate team to work with clients anywhere in the world. We have operated in the highlands of Porgera PNG, the coastal waters of Lihir PNG, the winters of Macraes NZ and the red dust of Murrin Murrin and on into the Central Queensland Oil and Gas Fields.

PPi provides a multi-discipline approach which maximises efficiency and minimises durations. PPi utilises process and mechanical engineers combined with skilled tradespeople to implement work and achieve results.

PPi bridges the gap between a pure engineering company and a labour hire company; we call this integrated service delivery... and it works.

A successful operation requires all stages of project development, implementation and operation to be suited to your particular ore deposit.

The PPi approach has been developed from our involvement with 11 gold autoclaves and 11 nickel autoclaves.

PPi’s one-team approach cuts time, saves money

PPi eliminates the time-consuming and costly task of having to recruit, assemble and coordinate a diverse number of individuals typically required for project start-up. Our personnel have a range of skills that cover numerous industries.

We provide our clients with a seamless, ready-made team of specialists, offering:

- A one team approach from construction completion, commissioning, start-up to ramp-up and ongoing maintenance and process optimisation

- A single point solution for new plant start-ups that will transition seamlessly from construction handover, through ramp up, to first maintenance shutdowns

- Complete integration with client project and operation teams

- Safety, once and right, with the degree of rigour to ensure success

- Remote site fly in fly out specialists anywhere in the world

- Detailed weekly status reports so you know what is happening each step of the way. Each report includes milestone achievements, forecasts, variations, slippage and additional work, issues and concerns, general activities and personnel details.

- Training of operational personnel

- We consider the training of our clients’ personnel an integral part of our services.

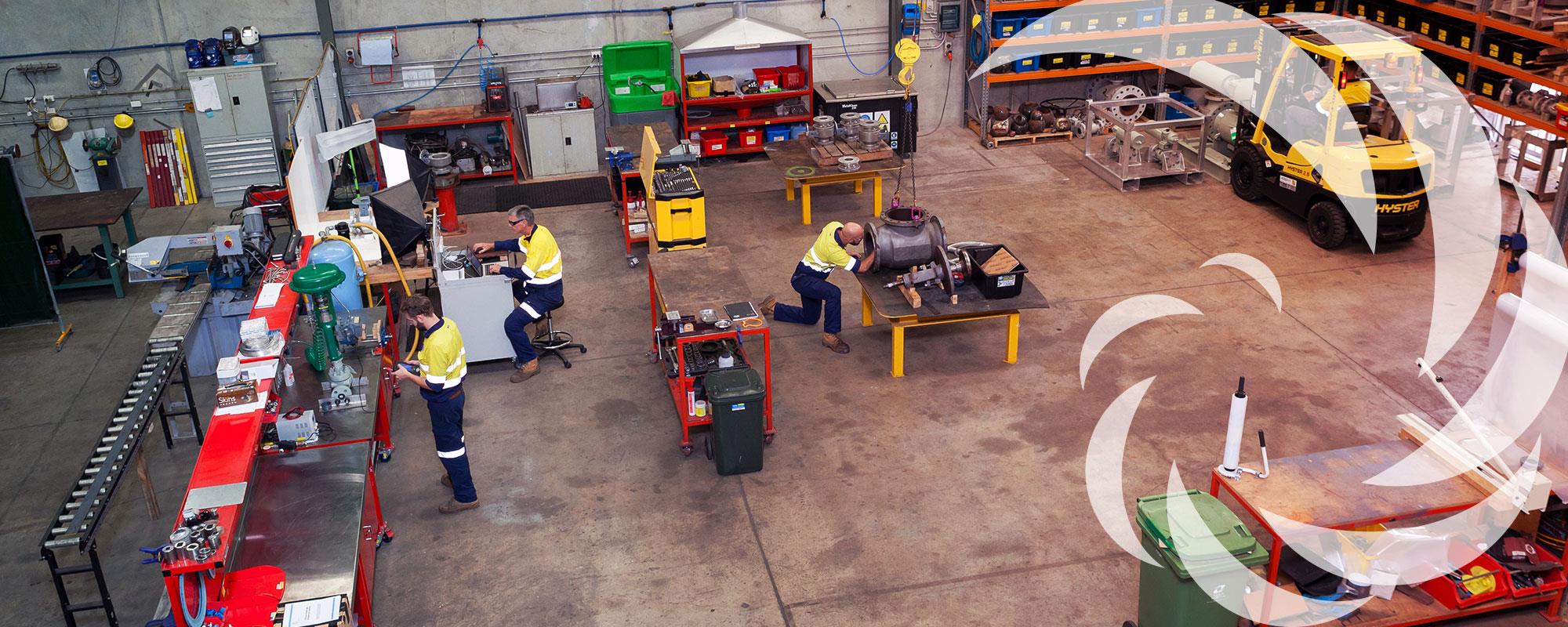

Workshop Services

And now with our state of the art workshop we can support the entire process with industry leading repairs and rebuilds of all manner of equipment. Specialising in valves and actuators used in high pressure processing plant applications, the workshop also conducts specialised welding processes on exotic materials using our in-house suite of welding procedures and welding inspectors. We pride ourselves on using leading edge engineering processes to develop solutions to complex problems.